- #Motor driver controller how to

- #Motor driver controller drivers

- #Motor driver controller driver

- #Motor driver controller upgrade

- #Motor driver controller full

#Motor driver controller driver

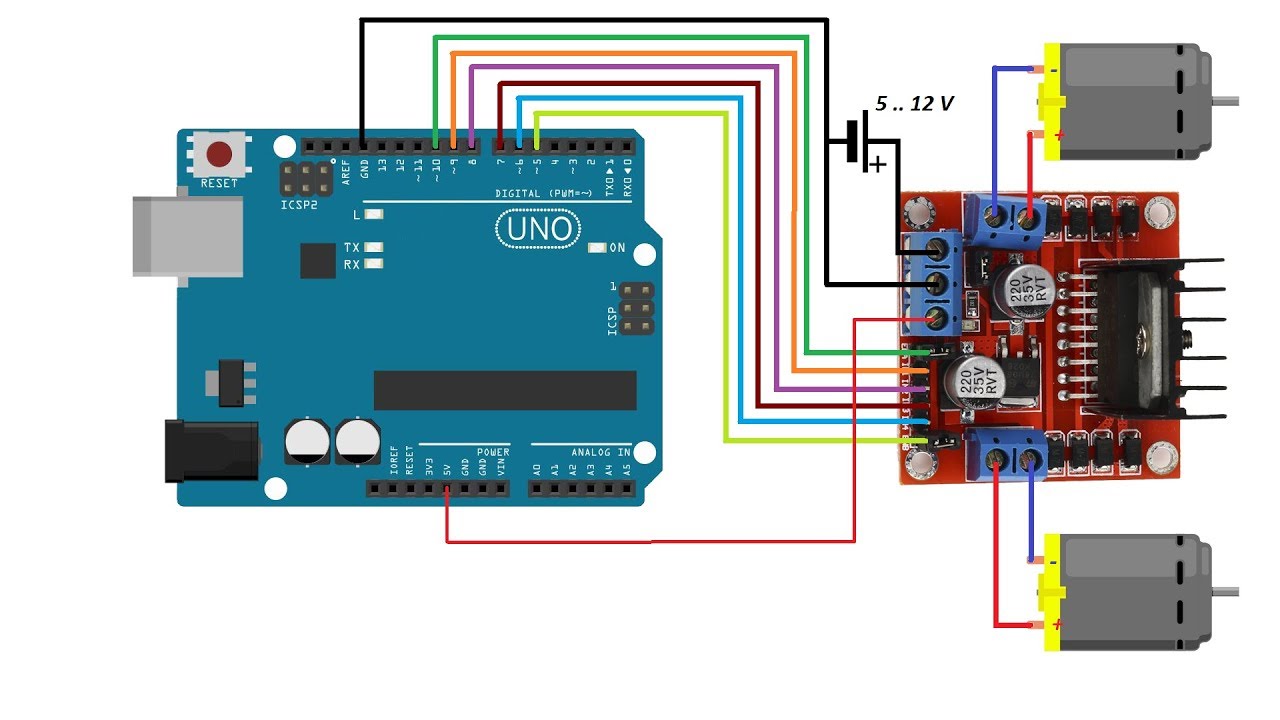

Once the driver get a pulse, the motor move a step.įor any questions, advice or cool ideas to share, please visit the DFRobot Forum. "PULSE" is the motor pulse signal pin."Direction" is the motor direction signal pin,.In this mode, you can adjust the motor shaft position manually when “EN” is High (Vacant), the motor will be in an automatic control mode. When “EN” is Low, the motor is in a free states (Off-line mode).The stepper motor rotates 6400 steps (a cycle), and reverses 6400 steps (a cycle). Up: OFF Down: "ON" Sample Code int PUL=7 //define Pulse pinįor (int i=0 i<6400 i++) //Forward 5000 stepsįor (int i=0 i<6400 i++) //Backward 5000 steps In this tutorial, we'll use a bipolar stepper motor, 1.8 step angle, 1.7A.More detail could be found on the User Guide.

#Motor driver controller how to

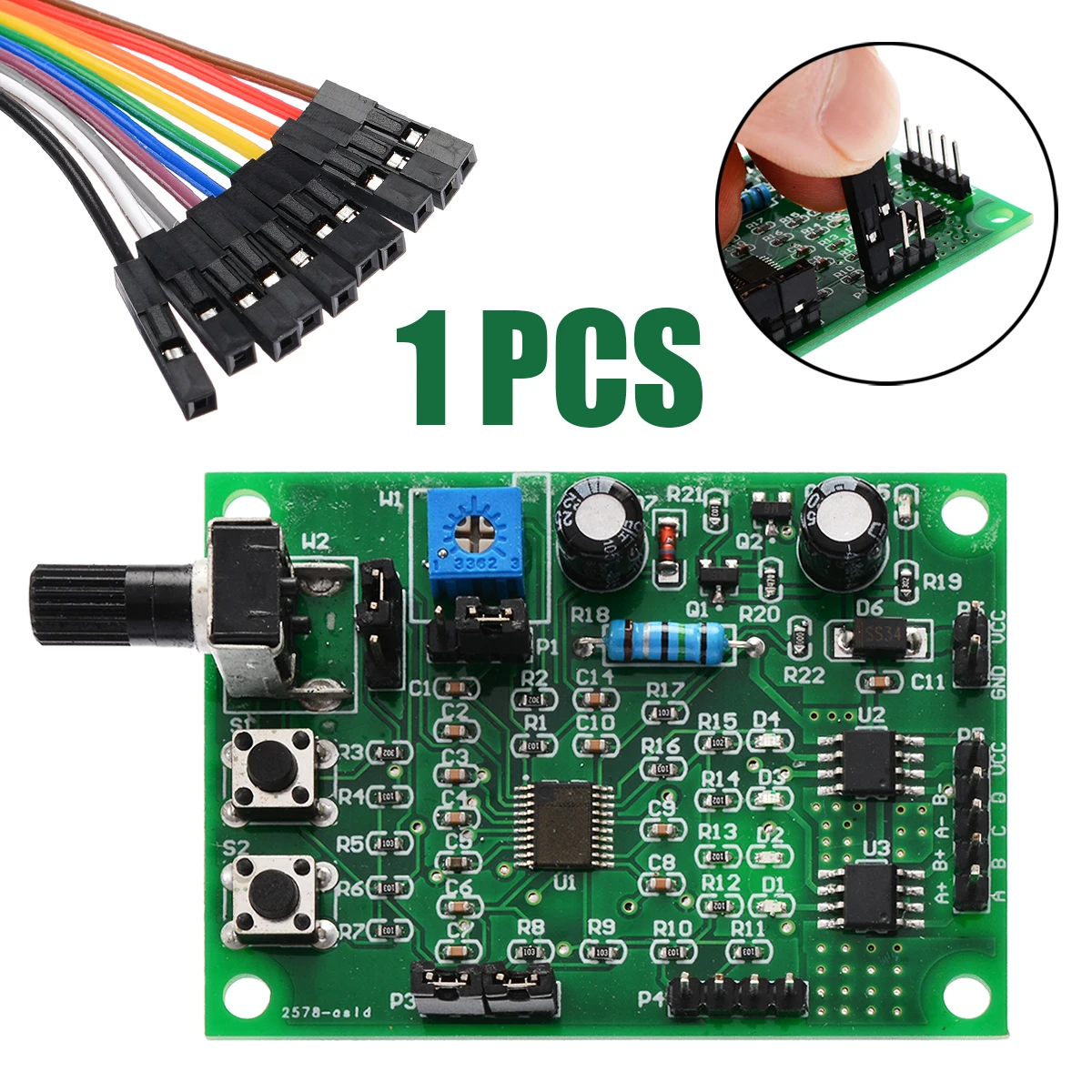

In this section, we'll show you how to use TB6600 arduino motor driver quickly. Overheat, over current and short circuit protection.Anti-high-frequency interference ability.The interface adopts high-speed optocoupler isolation.Support 7 kinds of micro steps adjustable.

#Motor driver controller upgrade

Note: this is a upgrade version of TB6600 Stepper Motor Driver. They connect to an encoder (not included), which monitors the position of the motor's shaft and reports back to the controller. Encoder-compatible controller/drivers are best when relative positioning is critical, such as coordinating motion in a multi-axis system. And all signal terminals adopt high-speed optocoupler isolation, enhancing its anti-high-frequency interference ability.Īs a professional device, it is able to drive 57, 42-type two-phase, four-phase, hybrid stepper motor. Choose a controller/driver rated at or below your motor’s maximum current. In the Dual SPDT motor driver circuit, the DC motor terminals are connected between the common poles of the two relays. With an H-bridge circuit, the polarity across a load can be altered in both directions. A Relay based DC motor controller works with an H-bridge arrangement. You can set its micro step and output current with 6 DIP switch. DC motor direction control using relay circuit.

The stepper driver supports speed and direction control. And it is able to output 4A peak current, which is enough for the most of stepper motors.

#Motor driver controller drivers

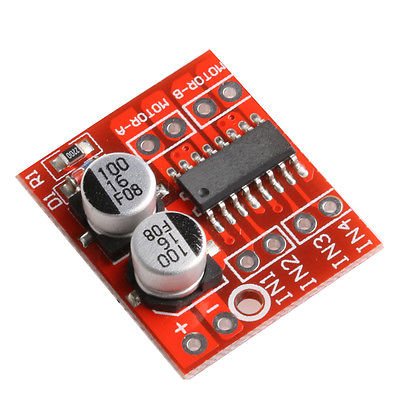

TB6600 arduino stepper motor driver has a wide range power input, 9~42VDC power supply. 3-Phase BLDC Motor-Control Block Diagram Gate Drivers L638x, L639x, L649x(1), STGAPxx Op. It is compatible with Arduino and other microcontrollers that can output a 5V digital pulse signal. Контроллеры CNC 2M542 Stepper Motor Driver Controller.TB6600 arduino Stepper Motor Driver is an easy-to-use professional stepper motor driver, which could control a two-phase stepping motor. Контроллеры CNC 2M542 Stepper Motor Driver Controller. Suitable for a wide range of stepping motors, from NEMA size 17 to 34įor advising, such as brand, architechture mould, badge, nameplate, display boards, doorplate, furniture decoration, etc.įor carving portrait, scenery, handwriting, sealing, etc.ġx M542 CNC Stepper Motor Driver (1.0A-4.5A)

Suitable for any small-and-medium automatic equipment with CNC controller, such as X-Y tables, labeling machines, laser cutters, engraving machines, and pick-place devices Short-voltage, over-voltage, over-current and short-circuit protection, protect the PC, motors, driver etc from being damaged TTL compatible and optically isolated inputĪutomatic half-current reduction as long as switching off SW4 when motors stopġ6 selectable resolutions in decimal and binary, up to 51,200 steps/rev Pure-sinusoidal current control technology

#Motor driver controller full

Self-adjustment technology, full to half current self-adjustment when motors from work to standstill via switching off SW4

It is suitable for driving 2-phase and 4-phase hybrid stepping motors, so the Nema17-Nema34 stepper motors with a 1.0A-4.5A current will be suitable. With this technology and the self-adjustment technology (self-adjust current control parameters) for different motors, the drive motors can run with smaller noise, lower heating, smoother movement and have better performances at higher speed than most of the drivers in the markets. The M542 Stepper Driver Board Controller is a high performance microstepping driver based on pure-sinusoidal current control technology.

0 kommentar(er)

0 kommentar(er)